Large-span Workshop

Company description

Cangzhou Hongsheng Steel Structure Co., Ltd. specializes in designing, manufacturing, processing and installing various steel structure projects for 15 years with 5 steel structure production lines and 50 tons production capacity each day. We would like to seek after win-win solution, and offer you our best price for long terms cooperation. Welcome to contact us for further discussion

Category:Hot selling product

Product Details

Specifications:

1) Main Steel: S355JR, S235JR, SS400, St52, Q345B, Q235B etc.

2) Column & Beam: builtup or Hot rolled H-section

3) Connection method of steel structure: welding connection or bolt connection

4) Wall & Roof: EPS, Rockwool, PU sandwich, corrugated color trapezoid steel sheet

5) Door: manual/ automatic Rolled up door or Sliding door

6) Window: Plastic steel or Aluminum alloy window

7) Surface: Hot dip galvanized or painted

8) Crane: 5MT, 10MT, 15MT 20MT and more

◆ Brief Description

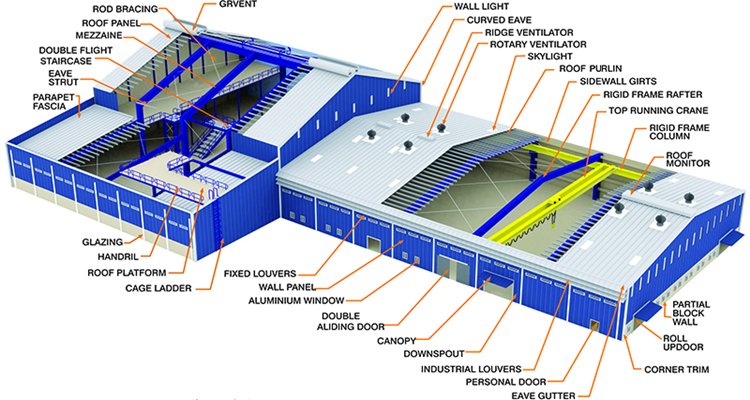

Steel structure frame is a Green economy building system, which is formed by the main structure (H-section steel for beam/column, C channel steel or Z channel steel for purlin), substructure (Round steel bar or Angle steel for bracing, Round steel tube for tie bar, Angle steel for angle brace), roof and wall system (using sandwich panel or single steel sheet), door and window system. Pre engineered steel structure building building is widely used as warehouse, workshop, hangar, shed, etc..

◆ Design capability

By using AutoCAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures (Xsteel) and etc. we can design complex industrial building like office mansion, super marker, auto dealer shop, shipping mall, 5 star hotel.

◆ Our Advantages

1. We design different types and sizes building according to customer’s needs, large or small, wide span: single span or multiple spans, the max span is 36m without middle column.

2. We proposal with low cost and maintenance: unit price range from USD25/m2 to USD50/m2 according to customers request.

3. The steel structure building fast construction and easy installation: time saving and labor saving, all the items are factory-made,pre-cut,pre-welded, pre-drilled,pre-painted or HDG in advance for saving cost and time.

4. Reduced construction waste, long using lifespan: up to 50 years.

5. We are using AutoCAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures (Xsteel) and etc software to design different buildings according to request of Clients. We service clients from design, produce, delivery and election.

We can design factors with Max. Wind 280KM/H, Earthquake Class C and Roof Snow Load 200kg/SQM.

6. Nice appearance and , Earthquake Resistance, Sound Insulation, Heating Insulation treatment.

7. Others: environmental protection, stable structure, High quake-proof, water proof and fire proof, and energy conserving.